In recent years, Saudi Arabia has seen a growing interest among government entities in organizing and managing their fixed assets . This aligns with broader goals such as digital transformation , improved governance, and enhanced spending efficiency. Numerous projects have been launched to inventory and tag assets—often using barcode technology.

While these initiatives typically start strong, many fail to maintain momentum and quickly lose their effectiveness. So, what’s the issue? And more importantly, how can it be resolved?

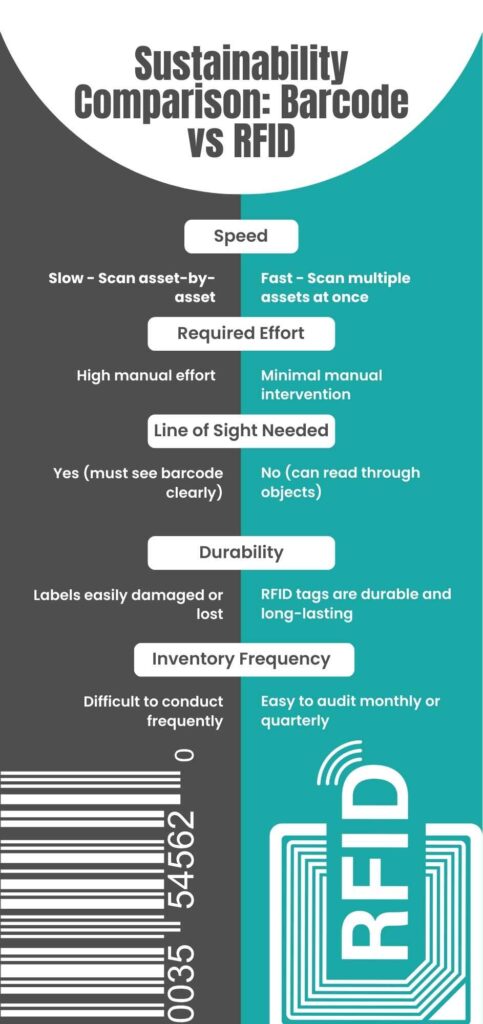

The Problem: Barcode-Based Inventory Is Not Sustainable

Barcode tagging is a widely used and cost-effective method for asset identification. However, it presents several challenges when applied to fixed asset environments, especially within large-scale government facilities:

1. Labor-Intensive Inventory Process

Barcode-based inventory requires manual scanning of each asset. This consumes significant time and human resources, especially in environments with thousands of assets across multiple locations.

2. Line-of-Sight Limitation

Barcodes must be clearly visible to be scanned. This often requires physically locating and repositioning assets—an inefficient and impractical process for assets that are fixed, hard to access, or frequently relocated.

3. Data Degradation Over Time

Barcode labels can fade, peel off, or become damaged, leading to incorrect or incomplete data. Over time, this undermines the reliability of the entire asset database.

4. Lack of Real-Time Integration

Most barcode systems operate in batch mode. This delays data updates and increases the risk of human error, especially during reconciliations or audits.

5. Low Motivation to Repeat the Process

After the initial tagging and inventory are completed, many entities find the periodic re-inventory too resource-heavy to justify. This results in abandoned projects and outdated records.

The Solution: RFID for Smart, Sustainable Asset Management

Radio Frequency Identification (RFID) technology offers a smarter and more sustainable alternative. It enables automatic, contactless, high-speed data capture without the need for line-of-sight. Here’s how RFID ensures sustainability in asset management:

1. Faster, More Accurate Inventory

RFID readers can capture data from multiple assets simultaneously—even those inside cabinets, on shelves, or in difficult-to-reach areas. This can reduce inventory time by up to 80%.

2. Effortless Periodic Audits

The ease of RFID scanning means that monthly or quarterly audits become feasible, allowing organizations to keep asset data current without major operational disruption.

3. Real-Time System Integration

Advanced RFID systems (like Tragging Fixed Assets ) send inventory data directly to the central database in real-time. This eliminates manual entry errors and speeds up reconciliation and reporting.

4. Smart Alerts & Asset Control

RFID-enabled systems can instantly flag missing or relocated assets and generate real-time alerts. This strengthens internal control and minimizes asset loss or misuse.

5. Long-Term Cost Efficiency

While RFID may require a higher upfront investment than barcodes, it delivers a strong return on investment by lowering operational costs, reducing audit time, and preventing asset mismanagement.

Conclusion

The issue isn’t with the intentions behind asset inventory projects—it’s with the tools used to implement them. Barcode systems are often effective at launch but lack the scalability and automation needed for long-term sustainability.

RFID technology, on the other hand, introduces a smarter, scalable approach that supports continuous improvement and real-time visibility—making it ideal for both government and private sector organizations aiming to modernize their asset management strategies.

At Tragging, we build sustainability into every solution. We help government agencies and enterprises establish intelligent, future-ready fixed asset systems that reduce manual work, improve accuracy, and ensure long-term success.